- HOME

- ABOUT US

- PRODUCT

- APPLICATION

- PROJECTS

- NEWS

- CONTACT US

-

Language

Language

Capacity : 6~50t/h

Pressure : 1.25~3.8Mpa

Fuel : wood chips, bagasse, straw, olive bone, coconut shell,peanut shell, pellets, rice husk and other biomass fuels

Application : Textile Industry, Food Industry, Sugar Industry, Paper Industry, Chemical Industry, Garment Industry, Waste Processing Industry, etc.

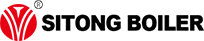

Brief Intro : SZL series double drums boiler is horizontal type water tube boiler with high steam quality. The boiler adopts membrane water wall, low thermal inertia design, and water cooling combustion chamber.

Email: [email protected]

1. Easy to install

Boiler is composed of upper body and chain grate 2 big parts, which only need to gather up and bricking the lower furnace, easy installation, lower cost and short time.2. Support a variety of biomass

Larger and higher furnace ensure the fully combustion, many kinds of biomass can be used on this boiler, strong applicability

3. Both sides air inlets

The boiler adopts double-side air inlet & independent air chamber structure, which can flexibly adjust the air volume and wind pressure of each air chamber to ensure the combustion performance.4. Remote monitoring

Advanced control system--remote monitoring, if there is any abnormality during the operation of the boiler, providing the first time guidance to reduce the failure rate and loss.

Steam Boiler

| Model |

Rated Steam Capacity (t/h) |

Working Pressure (MPa) |

Thermal Efficiency (%) |

Overall Dimension L×W×H (m) |

Weight (t) |

||

| SZL2-1.25/1.6/2.5 | 2 | 1.25/1.6/2.5 | 81 | 5.8×2.35×3.5 | 25 | ||

| SZL4-1.25/1.6/2.5 | 4 | 1.25/1.6/2.5 | 81 | 7.8×2.4×3.6 | 32 | ||

| SZL6-1.25/1.6/2.5 | 6 | 1.25/1.6/2.5 | 81 | 8×3×4.87 | 43 | ||

| SZL8-1.25/1.6/2.5 | 8 | 1.25/1.6/2.5 | 81 | 8.1×3.2×5.7 | 63 | ||

| SZL10-1.25/1.6/2.5 | 10 | 1.25/1.6/2.5 | 81 | 8.2×3.5×5.7 | 87 | ||

| SZL12-1.25/1.6/2.5 | 12 | 1.25/1.6/2.5 | 81 | 10.6×3.6×5.7 | 100 | ||

| SZL15-1.25/1.6/2.5 | 15 | 1.25/1.6/2.5 | 82 | 12.5×3.7×5.8 | 105 | ||

| SZL20-1.25/1.6/2.5 | 20 | 1.25/1.6/2.5 | 82 | 13.8×4.2×5.8 | 140 | ||

| SZL25-1.25/1.6/2.5 | 25 | 1.25/1.6/2.5 | 82 | 15.6×5×6.135 | 170 | ||

| SZL30-1.25/1.6/2.5 | 30 | 1.25/1.6/2.5 | 82 | 17.7×8.5×9.5 | 210 | ||

|

Note:1.Parameter is for reference only, if any changes should follow the factory technical data. 2. Our company can design boiler products based on customers’ requirement and different biomass fuels. |

|||||||

Hot Water Boiler

| Model | Rated Power (MW) | Working pressure (Mpa) | Supply water temperature (℃) | Return water temp (℃) | Thermal efficiency (%) | ||

| SZL1.4-0.7/95/70 | 1.4 | 0.7 | 95 | 70 | 80 | ||

| SZL2.8-0.7/95/70 | 2.8 | 0.7 | 95 | 70 | 80 | ||

| SZL4.2-1.0/95/70 | 4.2 | 1.0 | 95 | 70 | 80 | ||

| SZL5.6-1.0/95/70 | 5.6 | 1.0 | 95 | 70 | 80 | ||

| SZL7-1.0/95/70 | 7 | 1.0 | 95 | 70 | 80 | ||

| SZL10.5-1.0/115/70 | 10.5 | 1.0 | 115 | 70 | 80 | ||

| SZL14-1.0/115/70 | 14 | 1.0 | 115 | 70 | 80 | ||

|

Note: 1.Parameter is for reference only, if any changes should follow the factory technical data. 2. Our company can design boiler products based on customers’ requirement and different biomass fuels. |

|||||||

Sitong Boiler Co., Ltd is the professional manufacturer of Grade A industrial boilers, engages in industrial boiler design, manufacturing, transportation, installation, and after-sale service.

Online Chat