- HOME

- ABOUT US

- PRODUCT

- APPLICATION

- PROJECTS

- NEWS

- CONTACT US

-

Language

Language

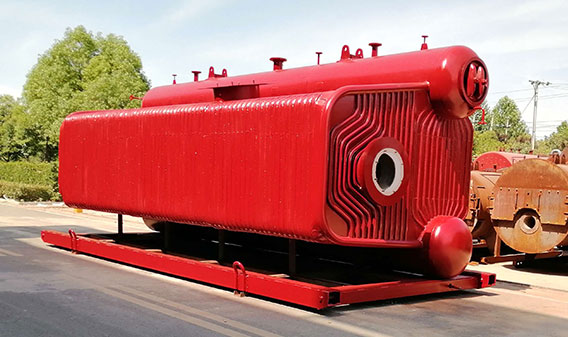

Capacity : 10~40t/h

Pressure : 1.0 MPa~ 4.9 MPa

Fuel : Natural Gas, Lpg, Diesel, Hfo, Bunker Oil, Furnace Oil

Application : Chemical industry ,Textile industry, paper making , food & beverage, Rubber Processing laundry, Wood Processing etc.

Brief Intro : SZS series water tube boiler has double drums, and arranged as “D” shape, adopts membrane cooling wall, has the characteristics of high steam quality, sufficient output, and high thermal efficiency (97%), etc.

Email: [email protected]

1. “D” shaped layout

The boiler adopts D-type arrangement and the flame fullness is good.2. Improve thermal efficiency

Two-stage energy saving devices are adpoted. economizer and condenser are always equipped on the rear or top of boiler,which can reduce the exhaust gas temperature and improve the thermal efficiency. The thermal efficiency can reach to 104% (fuel: natural gas l).

3. Sufficient output

The boiler has a surplus heating area and large enough steam water space to ensure sufficient and high quality steam output.4. Membrane wall structure

The furnace water wall and convection flue are all adopts membrane wall structure, which has good sealing performance and reduces the refractory bricks maintenance workload.

Steam Boiler

| Model |

Rated Evaporation (t/h) |

Rated Steam Temperature (℃) |

Working Pressure (Mpa) |

Water Supply Temperature (℃) |

Heating Area (㎡) |

Overall Dimension (mm) |

| SZS4-1.25-Y(Q) | 4 | 194 | 140 |

172 |

/ | 5700×1900×3600 |

| SZS10-1.25-Y(Q) | 10 | 194 | 1.25 | 20 | 340.23 | 8500×5865×4670 |

| SZS15-1.25-Q | 15 | 194 | 1 | 104 | 632.99 | 7970×4628×3470 |

| SZS20-1.25-Y(Q) | 20 | 194 | 1.25 | 105 | 556.64 | 12220×6895×4465 |

| SZS25-1.25-Y(Q) | 25 | 194 | 1.25 | 105 | 714 | 10860×70000×4850 |

| SZS30-2.45-Y(Q) | 30 | 225 | 2.45 | 105 | 767 | 12900×7000×4850 |

| SZS35-2.45-Y(Q) | 35 | 225 | 2.45 | 105 | 958 | 12910×7000×4850 |

| SZS50-2.45-Y(Q) | 50 | 225 | 2.45 | 105 | 1230 | 13200×12000×4700 |

|

Note: Parameter is for reference only, if any changes should follow the factory technical data. |

||||||

Hot Water Boiler

| Model |

Rated Power (MW) |

Working Pressure (Mpa) |

Heating Area (㎡) |

Fuel Consumption |

Overall Dimension (m) |

|||

| Light Oil (kg/h) | Natural Gas (Nm³/H) | |||||||

| SZS7-1.0/115/70-Y(Q) | 7 | 1.0 | 163 | 642 | 806 | 7.8×3.4×3.34 | ||

| SZS10.5-1.0/115/70-Y(Q) | 10.5 | 1.0 | 258 | 963 | 1137 | 7.1×3.66×3.5 | ||

| SZS14-1.25/115/70-Y(Q) | 14 | 1.25 | 245 | 1284 | 1551 | 10.2×6.6×4.8 | ||

| SZS21-1.25/130/70-Y(Q) | 21 | 1.25 | 394 | 1922 | 2322 | 12.3×7×5.4 | ||

| SZS46-1.6/130/70-Y(Q) | 46 | 1.6 | 1147 | 4203 | 4923 | 15.6×9.4×7.8 | ||

| Note: Parameter is for reference only,we can design the new products based on your requirement. | ||||||||

Sitong Boiler Co., Ltd is the professional manufacturer of Grade A industrial boilers, engages in industrial boiler design, manufacturing, transportation, installation, and after-sale service.

Online Chat