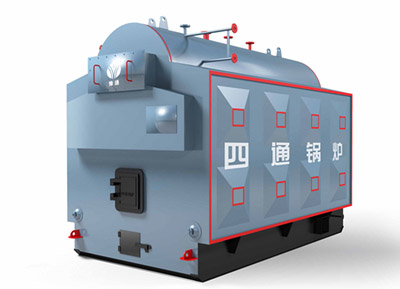

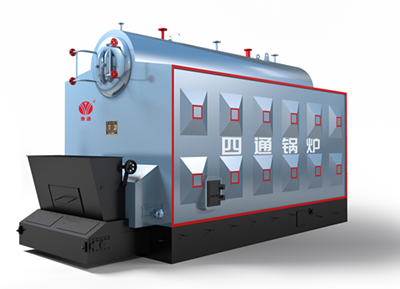

DH Series Corner Tube Boiler

- Evaporation Capacity :10~75 t/h

- Working Pressure :1.2~2.5Mpa

- Fuel :Different Type Biomass Fuel

- Application : Textile printing and dyeing, plastic and rubber, paper industry, wood industry, building material, chemical industry, etc.

- Brief Intro :Corner tube boiler is the high-tech product with international advanced technologies,has the characteristics of water circulation in safe and reliable.

Email: [email protected]

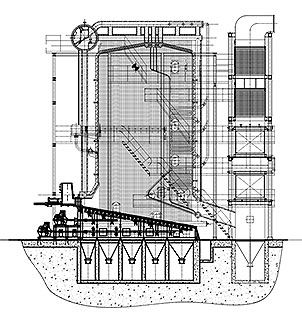

Corner tube boiler is the high-tech product with international advanced technologies, which use the technology of membrane water wall of power plant boiler to the industrial boiler, makes the boiler with better sealing performance and higher efficiency. Boiler water circulation system use the independent combination type of natural circulation and forced circulation, it has the characteristics of water circulation in safe and reliable.

Since the boiler was supported by the 4 down comer, and has the function of water distribution, so it was called corner tube boiler.

Corner tube boiler is the high-tech product with international advanced technologies, which use the technology of membrane water wall of power plant boiler to the industrial boiler, makes the boiler with better sealing performance and higher efficiency. Boiler water circulation system use the independent combination type of natural circulation and forced circulation, it has the characteristics of water circulation in safe and reliable.

Since the boiler was supported by the 4 down comer, and has the function of water distribution, so it was called corner tube boiler.

Technical Advantages

1. large furnace with full membrane sealing structure, more suitable for the combustion of biomass boiler. Lower heat loss, higher thermal efficiency.

2. Larger water cooling degree reduce the risk of coking, more suitable for the larger capacity boilers.

3. Secondary air design make the air distribution more uniformly and better combustion performance, it also can reduce the generation of nitrogen oxides.

4. Independent furnace arch design, suitable for many kinds of biomass.

5. It adopts to the corrsgirder grate, less running resisitance, better cooling performance, lower breakdown rate, less fuel leakage.

Parameter

| Model | Steam Capacity(t/h) | Rated Pressure (Mpa) | Thermal Efficiency | Design Fuel |

| DHW20-1.25/1.6/2.0/2.5/3.0-AII | 20 | 1.25/1.6/2.0/2.5/3.0 | 88% | Bituminous coal, wood chips, pellet, husk, shell etc. |

| DHW25-1.25/1.6/2.0/2.5/3.0-AII | 25 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW30-1.25/1.6/2.0/2.5/3.0-AII | 30 | 1.25/1.6/2.0/2.5/3.0 |

88% |

|

| DHW35-1.25/1.6/2.0/2.5/3.0-AII | 35 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW40-1.25/1.6/2.0/2.5/3.0-AII | 40 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW50-1.25/1.6/2.0/2.5/3.0-AII | 50 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW75-1.25/1.6/2.0/2.5/3.0-AII | 75 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| Note: Parameter is for reference only, if any changes should follow the actual drawing | ||||

Technical Advantages

1. large furnace with full membrane sealing structure, more suitable for the combustion of biomass boiler. Lower heat loss, higher thermal efficiency.

2. Larger water cooling degree reduce the risk of coking, more suitable for the larger capacity boilers.

3. Secondary air design make the air distribution more uniformly and better combustion performance, it also can reduce the generation of nitrogen oxides.

4. Independent furnace arch design, suitable for many kinds of biomass.

5. It adopts to the corrsgirder grate, less running resisitance, better cooling performance, lower breakdown rate, less fuel leakage.

Parameter

|

|||||||||||||||||||||||||||||||||||||||

Parameter

| Model | Steam Capacity(t/h) | Rated Pressure (Mpa) | Thermal Efficiency | Design Fuel |

| DHW20-1.25/1.6/2.0/2.5/3.0-AII | 20 | 1.25/1.6/2.0/2.5/3.0 | 88% | Bituminous coal, wood chips, pellet, husk, shell etc. |

| DHW25-1.25/1.6/2.0/2.5/3.0-AII | 25 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW30-1.25/1.6/2.0/2.5/3.0-AII | 30 | 1.25/1.6/2.0/2.5/3.0 |

88% |

|

| DHW35-1.25/1.6/2.0/2.5/3.0-AII | 35 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW40-1.25/1.6/2.0/2.5/3.0-AII | 40 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW50-1.25/1.6/2.0/2.5/3.0-AII | 50 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| DHW75-1.25/1.6/2.0/2.5/3.0-AII | 75 | 1.25/1.6/2.0/2.5/3.0 | 88% | |

| Note: Parameter is for reference only, if any changes should follow the actual drawing | ||||

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.