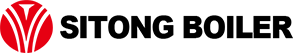

AAC Autoclave

- Design Pressure :1.0-3.8 Mpa

- Design Temperature :187-225°C

- Length :According to the customers demands

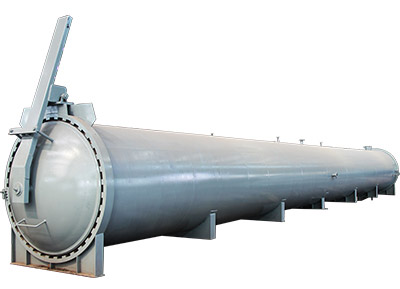

- Application : AAC Plant (Autoclaved Aerated Concrete Plant)

- Brief Intro :AAC autoclave is large pressure vessel for steam curing, has excellent thermal insulating quality. It has the advantages of good treat efficiency, large capacity, reasonable layout, and safety & convenient operation, etc.

Email: [email protected]

Autoclave for AAC plant is large pressure vessel for steam curing, has excellent thermal insulating quality, and it supporting the use of steam boilers. The autoclave is a horizontal cylinder device, when curing the aerated concrete, there is hydrothermal reaction (CaO-SiO2-H2O) happened in autoclave. It has the advantages of wide applicability, good treat efficiency, large capacity, reasonable layout, and safety operation, etc. Sitong Boiler could design and manufacture various forms of autoclave according to customers’ requirements.

Except AAC plant, the autoclave could also be used for wood preservation, maintenance and steaming of lime-sand brick, fly-ash brick, new light wall material, concrete tubular pile and other building products, moreover, it can used for the products steaming in chemical industry, medicine, rubber, wood corrosion prevention, gypsum, glass, thermal insulation materials, textile, war industry and other area.

Advantages

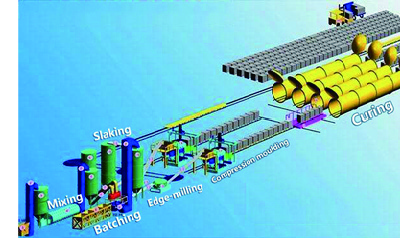

1. High quality materials

1. High quality materials

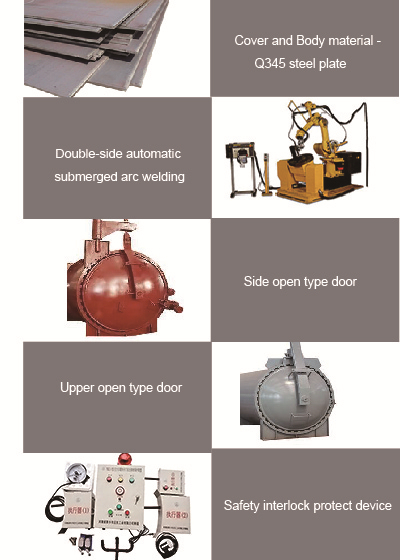

The autoclave cover uses monoblock Q345R steel plate for compression moulding, and the flange of autoclave cover and body use Q345R steel plate for integral forgoing, to ensure the high quality.

2. Advanced processing technology

Double-side automatic submerged arc welding are used for the weld joint of autoclave cover head and flange, and then heat treatment and strict nondestructive testing are processed for all weld joint of pressure parts, eliminate forging stress and welding stress.

3. Special and convenient structure

There are two open types, and the door could be designed as manual operated or automatic operated.

1) Side open type using the rotating arm type door - opening structure. Flexible rotation, low post operation, simple and convenient opening.

2) Upper open type door using the lever type door-opening structure, lower leverage connect with kettle door, the top part equipped with counterweight device, open portable and occupies small space.

4. Safe operation

Equipped with sophisticated safe interlock protection device, utmost avoid the potential wrong operation, to ensure the safe operation.

5. Boiler customization

Sitong boiler could customize the autoclave based on the requested length, width, or pressure.

Parameter

| Model | Internal diameter (m) | Effective length(m) | Designed pressure(Mpa) | Designed temperature(°C) | Working medium | Length×Wide×Height (mm) | Weight (ton) | ||

| FGZCS1.0-1.65×21 | 1.65 | 21 | 1 | 187 | Saturation steam | 22650×2619×2695 | 21.5 | ||

| FGZCS1.3-2×21 | 2 | 21 | 1.3 | 198 | 23300×2980×3340 | 24.7 | |||

| FGZCS1.3-2×27 | 2 | 27 | 1.3 | 198 | 2930×2980×3340 | 30.5 | |||

| FGZCS1.3-2×31 | 2 | 31 | 1.3 | 198 | 33300×2980×3340 | 33.4 | |||

| FGZCS1.3-2.5×27 | 2.5 | 27 | 1.3 | 198 | 29560×3254×4117 | / | |||

| FGZCS1.3-2×31 | 2.5 | 31 | 1.3 | 198 | 33560×3254×4117 | / | |||

|

Notes: 1. Parameter is for reference only, if any changes should follow actual drawings. 2.We can design the specific industrial autoclave based on customers’ requirement. |

|||||||||

1. High quality materials

The autoclave cover uses monoblock Q345R steel plate for compression moulding, and the flange of autoclave cover and body use Q345R steel plate for integral forgoing, to ensure the high quality.

2. Advanced processing technology

Double-side automatic submerged arc welding are used for the weld joint of autoclave cover head and flange, and then heat treatment and strict nondestructive testing are processed for all weld joint of pressure parts, eliminate forging stress and welding stress.

3. Special and convenient structure

There are two open types, and the door could be designed as manual operated or automatic operated.

1) Side open type using the rotating arm type door - opening structure. Flexible rotation, low post operation, simple and convenient opening.

2) Upper open type door using the lever type door-opening structure, lower leverage connect with kettle door, the top part equipped with counterweight device, open portable and occupies small space.

4. Safe operation

Equipped with sophisticated safe interlock protection device, utmost avoid the potential wrong operation, to ensure the safe operation.

5. Boiler customization

Sitong boiler could customize the autoclave based on the requested length, width, or pressure.

| Model | Internal diameter (m) | Effective length(m) | Designed pressure(Mpa) | Designed temperature(°C) | Working medium | Length×Wide×Height (mm) | Weight (ton) | ||

| FGZCS1.0-1.65×21 | 1.65 | 21 | 1 | 187 | Saturation steam | 22650×2619×2695 | 21.5 | ||

| FGZCS1.3-2×21 | 2 | 21 | 1.3 | 198 | 23300×2980×3340 | 24.7 | |||

| FGZCS1.3-2×27 | 2 | 27 | 1.3 | 198 | 2930×2980×3340 | 30.5 | |||

| FGZCS1.3-2×31 | 2 | 31 | 1.3 | 198 | 33300×2980×3340 | 33.4 | |||

| FGZCS1.3-2.5×27 | 2.5 | 27 | 1.3 | 198 | 29560×3254×4117 | / | |||

| FGZCS1.3-2×31 | 2.5 | 31 | 1.3 | 198 | 33560×3254×4117 | / | |||

|

Notes: 1. Parameter is for reference only, if any changes should follow actual drawings. 2.We can design the specific industrial autoclave based on customers’ requirement. |

|||||||||

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.