LSH Series Vertical Biomass Steam Boiler

- Capacity :0.1t/h-1t/h

- Pressure :0.4/0.7Mpa

- Fuel :wood chips, straw, rice hull, bagasse, and other biomass fuels

- Application : Textile industry, food industry, wood factory, paper plant, chemical industry, garment industry, etc.

- Brief Intro :The boiler is vertical type small capacity boiler with horizontal water tubes, compare with older boiler, temperature rise up faster, save energy, lower cost and higher thermal efficiency.

Email: [email protected]

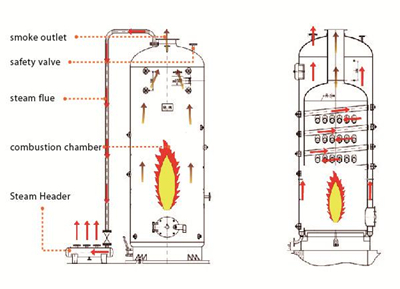

LSH series vertical type biomass steam boiler is a small capacity boiler with horizontal water tubes. Flue gas is brushing the inner wall of furnace and water tubes, for radiation heat transfer and convection heat transfer, the grate and lower part of furnace is radiation heating area, the horizontal water tubes and upper part of furnace is convection heating area. It has the advantages of compact structure, small footprint, and save infrastructure cost. Sitong Boiler has a mature R&D and design team, could customize the boilers based on customers’ requirement.

This vertical type biomass boiler adopts the general combustion techniques, the combustion equipment is moving grate, coal or biomass fuel was fed by workers manually. After burning in the moving grate, the exhaust gas passes through the horizontal water tubes, and the small carbon black and dust fall down onto the grate for reburning, and then the exhaust gas is released to the atmosphere through the chimney.

Technical Advantages

1. Large Heating Area

1) Horizontal pipes increase the radiation heating area, the flue gas pass through the forced convection tube bundle longitudinally, fully absorb the flue gas heat, decrease exhaust gas temperature, high thermal efficiency.

2) Low fuel consumption, compare with the older boiler, save 25%~30% energy.

2. Multi-pass structure

high heat transfer efficiency, moreover, the dust in flue gas can be removed naturally without ID fan, save energy.

3. Insulating Layer

The boiler uses aluminium silicate board for heat preservation, low heat loss. Moreover, the shell could adopts stainless steel, the appearance is much more delicate.

4. Natural ventilation

The steam boiler is natural ventilation, do not need ID fan and draft fan, operate quiet.

5. Economizer

Economizer could be arranged at the tail of boiler to improve the thermal efficiency.

6. Compact Structure

The boiler is vertical type with small steam capacity, small footprint, easy to install, low investment. Moreover, the temperature and pressure rise-up quickly.

Parameter

| Model | Rated Evaporation(t/h) | Working Pressure (Mpa) | Steam Temperature (°C) | Heating Transfer Area (m2) | Grate Area (m2) | Overall Size (m) |

| LSH0.3-0.4 | 0.3 | 0.4 | 151 | 9.0 | 0.5 | 1.0×3.4 |

| LSH0.5-0.4 | 0.5 | 0.4 | 151 | 18.3 | 0.78 | 1.2×3.7 |

| LSH1-0.4 | 1 | 0.4 | 151 | 38.6 | 1.54 | 1.6×4.8 |

| LSH0.3-0.7 | 0.3 | 0.7 | 170 | 10.6 | 0.5 | 1.0×3.6 |

| LSH0.5-0.7 | 0.5 | 0.7 | 170 | 20.5 | 0.78 | 1.2×4.0 |

| LSH1-0.7 | 1 | 0.7 | 170 | 46.3 | 1.54 | 1.6×4.9 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||

1. Large Heating Area

1) Horizontal pipes increase the radiation heating area, the flue gas pass through the forced convection tube bundle longitudinally, fully absorb the flue gas heat, decrease exhaust gas temperature, high thermal efficiency.

2) Low fuel consumption, compare with the older boiler, save 25%~30% energy.

2. Multi-pass structure

high heat transfer efficiency, moreover, the dust in flue gas can be removed naturally without ID fan, save energy.

3. Insulating Layer

The boiler uses aluminium silicate board for heat preservation, low heat loss. Moreover, the shell could adopts stainless steel, the appearance is much more delicate.

4. Natural ventilation

The steam boiler is natural ventilation, do not need ID fan and draft fan, operate quiet.

5. Economizer

Economizer could be arranged at the tail of boiler to improve the thermal efficiency.

6. Compact Structure

The boiler is vertical type with small steam capacity, small footprint, easy to install, low investment. Moreover, the temperature and pressure rise-up quickly.

| Model | Rated Evaporation(t/h) | Working Pressure (Mpa) | Steam Temperature (°C) | Heating Transfer Area (m2) | Grate Area (m2) | Overall Size (m) |

| LSH0.3-0.4 | 0.3 | 0.4 | 151 | 9.0 | 0.5 | 1.0×3.4 |

| LSH0.5-0.4 | 0.5 | 0.4 | 151 | 18.3 | 0.78 | 1.2×3.7 |

| LSH1-0.4 | 1 | 0.4 | 151 | 38.6 | 1.54 | 1.6×4.8 |

| LSH0.3-0.7 | 0.3 | 0.7 | 170 | 10.6 | 0.5 | 1.0×3.6 |

| LSH0.5-0.7 | 0.5 | 0.7 | 170 | 20.5 | 0.78 | 1.2×4.0 |

| LSH1-0.7 | 1 | 0.7 | 170 | 46.3 | 1.54 | 1.6×4.9 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||

Case

-

1Ton LSH Series Vertical Type Coal Fired Steam Boiler for Weaving Front Process

Sitong LSH series vertical coal/biomassboiler uses the general combustion technique. The coal/biomass fuel is fed by workers manually.

Learn more >>

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.