Once Through Structure Steam Boiler

- Capacity :0.1~4 t/h

- Pressure :Atmospheric pressure

- Fuel :light oil, diesel, natural gas, LPG

- Application : Heating, molding, drying, hotel, swimming pool, restaurant ,food processing .etc.

- Brief Intro :Once through steam boiler is vertical type boiler with small steam capacity, the efficiency is about 96%, it could generate steam within 3~5 minutes after ignition.

Email: [email protected]

Application

The once through steam boiler has the advantages of high thermal efficiency, quick steam generate, small area occupied, and energy saving, it could be used for heating, molding, and drying during industrial production, where need small steam capacity needed in peak time. Moreover, it could used for restaurant, swimming pool, hotel, school heating supply , etc.

Performance Advantages

1. Quick Steam Generation

1. Quick Steam Generation

Equipped with advanced once-through structure, and the small water capacity achieves fast heat absorption, high thermal efficiency .Prompt steaming after 3-5minutes lighting, with sufficient steam output after 3-5minute lighting , immediately work is available

2. High Efficiency Skid-Mounted Type

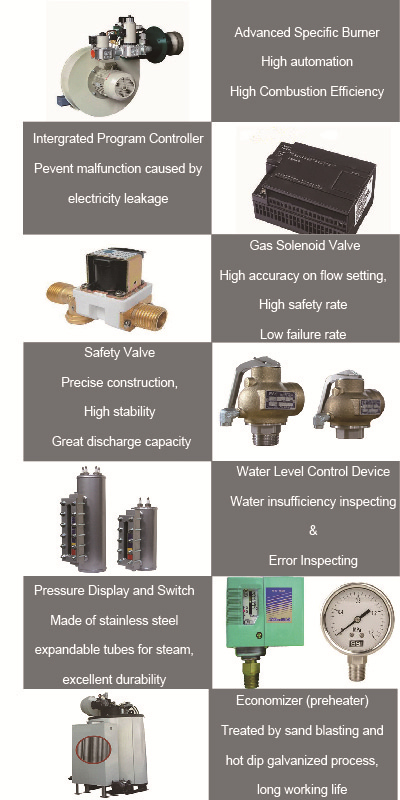

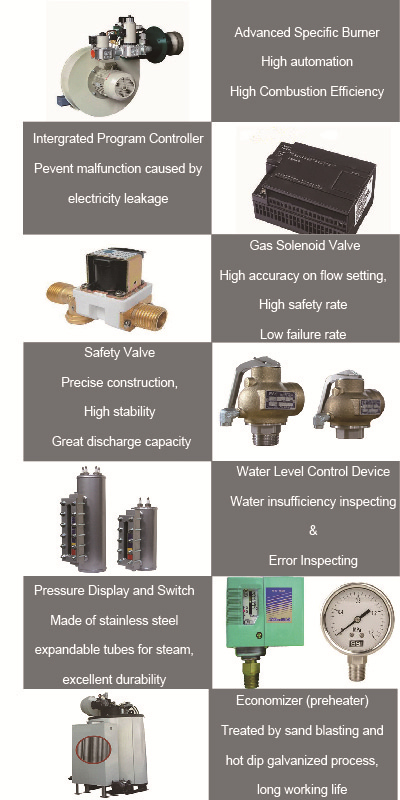

1) Equipped with specific burner, high automation and combustion efficiency, low NOx emission.

2) Increases the layout of horizontal fins and vertical fins based on the boiler capacity, combustion gas flows among the water tube bundle at a high speed, good heat transfer, excellent heat convection and fast heat transfer efficiency.

3) By equipping with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency increase to as high as 96%.

3. Full Automatic Control

1) The burner is full automatic, stable operation.

2) Full automatic interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

4. High Safety Performance

1) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

2) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

5. High Quality

1) All the materials has quality certificate, uses full automatic CO2 welding, NDT test and hydraulic pressure will be done for all boilers to ensure the quality.

2) The preheater uses seamless steel pipes, which are treated by sand blasting and hot-dip galvanizing, lengthen the working life.

6. Centralized Control is Available

Several boilers could be used in parallel, and controlled centrally. Moreover, the centralized controller could record the downtime, location, evaporation capacity, fuel consumption, water volume, steam pressure, water tube temperature, exhaust smoke temperature, etc.

Parameter

| Model |

Heat Output (Kcal/h) |

Working Pressure (Kgf/cm2) |

Boiler Efficiency (%) |

Overall Dimension L×W×H(mm) |

Weight (Kg) |

Fuel Consumption | |||

| 13A (Nm3/h) | LPG Propane (Kg/h) | LPG Butane (Kg/h) | |||||||

| ZH-200G | 108000 | 10 | 96 | 1154×788×1615 | 470 | 12.4 | 10.7 | 11.3 | |

| ZH-300G/GE | 162000 | 10 | 96 | 1279/1447×915×1804 | 620/720 | 18 | 15.5 | 16.5 | |

| ZH-500GE/GE1 | 269000 | 10 | 96 | 1612/1612×1098×2115 | 1060/1060 | 30 | 26 | 27 | |

| ZH-600GE/GE1 | 323000 | 10 | 96 | 1612/1612×1098×2115 | 1100/1100 | 36 | 31 | 33 | |

| ZH-1000GE1/GE2 | 539000 | 10 | 96 | 1750/1809×1456×2222 | 1600/1690 | 85~90 | 73~78 | 77~82 | |

| ZH-2000GE1/GE2 | 1080000 | 10 | 96 | 1830/1855×1908×2307 | 1980/2000 | 113~121 | 98~105 | 103~110 | |

|

Notes: 1. Parameter is for reference only. 2. The Lower heat valve: 13A=9900kcal/Nm3, LPG Propane=11460kcal/kg, LPG Butane=10900kcal/kg |

|||||||||

1. Quick Steam Generation

1. Quick Steam Generation

Equipped with advanced once-through structure, and the small water capacity achieves fast heat absorption, high thermal efficiency and the steam could be generated within 3~5 minutes.

2. High Efficiency

1) Equipped with specific burner, high automation and combustion efficiency, low NOx emission.

2) Increases the layout of horizontal fins and vertical fins based on the boiler capacity, combustion gas flows among the water tube bundle at a high speed, excellent heat convection and fast heat transfer efficiency.

3) By equipping with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency increase to as high as 96%.

3. Full Automatic Control

1) The burner is full automatic, stable operation.

2) Full automatic interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

4. High Safety Performance

1) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

2) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

5. High Quality

1) All the materials has quality certificate, uses full automatic CO2 welding, NDT test and hydraulic pressure will be done for all boilers to ensure the quality.

2) The preheater uses seamless steel pipes, which are treated by sand blasting and hot-dip galvanizing, lengthen the working life.

6. Centralized Control

Several boilers could be used in parallel, and controlled centrally. Moreover, the centralized controller could record the downtime, location, evaporation capacity, fuel consumption, water volume, steam pressure, water tube temperature, exhaust smoke temperature, etc.

| Model |

Heat Output (Kcal/h) |

Working Pressure (Kgf/cm2) |

Boiler Efficiency (%) |

Overall Dimension L×W×H(mm) |

Weight (Kg) |

Fuel Consumption | |||

| 13A (Nm3/h) | LPG Propane (Kg/h) | LPG Butane (Kg/h) | |||||||

| ZH-200G | 108000 | 10 | 96 | 1154×788×1615 | 470 | 12.4 | 10.7 | 11.3 | |

| ZH-300G/GE | 162000 | 10 | 96 | 1279/1447×915×1804 | 620/720 | 18 | 15.5 | 16.5 | |

| ZH-500GE/GE1 | 269000 | 10 | 96 | 1612/1612×1098×2115 | 1060/1060 | 30 | 26 | 27 | |

| ZH-600GE/GE1 | 323000 | 10 | 96 | 1612/1612×1098×2115 | 1100/1100 | 36 | 31 | 33 | |

| ZH-1000GE1/GE2 | 539000 | 10 | 96 | 1750/1809×1456×2222 | 1600/1690 | 85~90 | 73~78 | 77~82 | |

| ZH-2000GE1/GE2 | 1080000 | 10 | 96 | 1830/1855×1908×2307 | 1980/2000 | 113~121 | 98~105 | 103~110 | |

|

Notes: 1. Parameter is for reference only. 2. The Lower heat valve: 13A=9900kcal/Nm3, LPG Propane=11460kcal/kg, LPG Butane=10900kcal/kg |

|||||||||

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.