CDZH Coal Fired Hot Water Boiler

- Capacity :0.35MW~5.6MW

- Pressure :Atmospheric pressure

- Fuel :coal

- Application : greenhouse, hotel, school, hotel, gym

- Brief Intro: :CDZH coal fired hot water boiler uses the new scientific achievement, solves the problem of low thermal efficiency, tube plate cracking, drum bulging, insufficient output, and environment pollution.

Email: [email protected]

The CDZH coal fired hot water boiler realizes almost zero pollution with the use of special dust collector solution (bag dust collector, double towers desulfurization, etc.), it is honored as Chinese famous brand. This series boiler is shell type three-pass structure boiler with single drum or double drums. Generally, the steam capacity higher than 10t/h is designed as double drums to offer the sufficient output. The combustion equipment is stoker (small scale flaker is available), has the advantages of feed mechanically, strong adaptability of different fuels, low coal leakage, and convenient maintenance. The fuel is coal, the diameter should be 6-25mm, and ash content should be less than 32.4%.

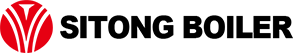

This coal fired boiler uses the new scientific achievement, such as arch tube plate, spirally corrugated tube to solve the problem of low thermal efficiency, tube plate cracking, drum bulging, insufficient output, and environmental pollution. Sitong Boiler has a mature R&D and design team, could customize the boilers based on customers’ requirement.

Application:

Performance Advantages

1. High thermal efficiency

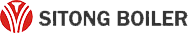

1)The spirally corrugated tube strengthen the heat transfer, improve thermal efficiency. The flue gas has the foundation of disturbance, avoid ash depositing in tube.

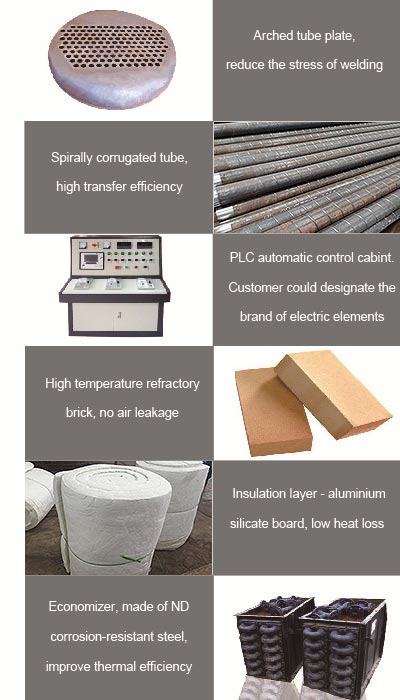

2)The furnace wall was poured entirely by the heat-resistance concrete and high-temperature-resistance refractory brick, excellent leakproofness, no air leakage. Moverover, the boiler shell use aluminium silicate board for heat preservation, low heat loss.

3) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, increase thermal efficiency.

2. Avoid bulging

The riser tube bundle under the drum, remove the dead water region at the bottom of drum, sludge is not easy for depositing, the high temperature area of drum has better cooling, prevent bulging.

3. Avoid tube plate cracking

1) Arched tube plate and spirally corrugated tube, change the quasi-steel body into quasi-elastic body structure, reduce stress.

2) Gas duct in drum on both sides, the smoke gas could enter into the front smoke chamber smoothly, the temperature of tube plate is lower than 600℃, avoid cracking leaded by high temperature.

4. Sufficient output

Horizontal type three pass structure and large furnace diameter boiler drum.

5. Environmental protection

1) The splayed wall and smoke outlet have the function of dust removal, decrease the concentration of smoke emission.

2) The moving grate boiler adopts several environmental protect measures (bag dust collector, double towers desulfurization, etc.) to meet the national emission requirement.

Parameter

Note: 1. Parameter is for reference only, if any changes should follow the factory technical data.

2. Available fuel: II class bituminous coal, lower heating value: Q≈21,000 KJ/Kg

Model

Rated power (MW)

Rated

pressure(Mpa)

Supply water

temperature(℃)

Return water

temperature(℃)

Efficiency (%)

Size (m)

Weight (t)

CDZH0.7-95/70-AII

0.7

Normal pressure

95

70

78

2.5x1.7x2.4

8

CDZH1.4-95/70-AII

1.4

Normal pressure

95

70

78

3.4x2.2x2.6

11

DZH2.8-95/70-AII

2.8

Normal pressure

95

70

78

4.3x2.5x3

15

1. High thermal efficiency

1)The spirally corrugated tube strengthen the heat transfer, improve thermal efficiency. The flue gas has the foundation of disturbance, avoid ash depositing in tube.

2)The furnace wall was poured entirely by the heat-resistance concrete and high-temperature-resistance refractory brick, excellent leakproofness, no air leakage. Moverover, the boiler shell use aluminium silicate board for heat preservation, low heat loss.

3) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, increase thermal efficiency.

2. Avoid bulging

The riser tube bundle under the drum, remove the dead water region at the bottom of drum, sludge is not easy for depositing, the high temperature area of drum has better cooling, prevent bulging.

3. Avoid tube plate cracking

1) Arched tube plate and spirally corrugated tube, change the quasi-steel body into quasi-elastic body structure, reduce stress.

2) Gas duct in drum on both sides, the smoke gas could enter into the front smoke chamber smoothly, the temperature of tube plate is lower than 600℃, avoid cracking leaded by high temperature.

4. Sufficient output

Horizontal type three pass structure and large furnace diameter boiler drum.

5. Environmental protection

1) The splayed wall and smoke outlet have the function of dust removal, decrease the concentration of smoke emission.

2) The moving grate boiler adopts several environmental protect measures (bag dust collector, double towers desulfurization, etc.) to meet the national emission requirement.

| Model | Rated power (MW) |

Rated pressure(Mpa) |

Supply water temperature(℃) |

Return water temperature(℃) |

Efficiency (%) | Size (m) | Weight (t) | |

| CDZH0.7-95/70-AII | 0.7 | Normal pressure | 95 | 70 | 78 | 2.5x1.7x2.4 | 8 | |

| CDZH1.4-95/70-AII | 1.4 | Normal pressure | 95 | 70 | 78 | 3.4x2.2x2.6 | 11 | |

| DZH2.8-95/70-AII | 2.8 | Normal pressure | 95 | 70 | 78 | 4.3x2.5x3 | 15 | |

|

Note: 1. Parameter is for reference only, if any changes should follow the factory technical data. 2. Available fuel: II class bituminous coal, lower heating value: Q≈21,000 KJ/Kg |

||||||||

Case

- 1

- 2

- 3

- 4

-

4ton DZH Series Coal Fired Chain Grate Boiler for Philippines Palm Oil Mill

1. Thermal efficiency (83%)

Learn more >>

2. Convenient for installation and maintain

3. Membrane water wall structure and spark holding wall -

8ton SZL Series Chain Grate Steam Boiler for Bangladesh Gypsum Boards Factory

1. Strong adaptability of solid fuels: coal, wood, biomass pellet, etc

Learn more >>

2. Whole membrane water cooling combustion chamber and inverted "α" arch furnace technology achieve high combustion efficiency, high output -

10ton SZL Series Coal Fired Steam Boiler for Zambia Alcohol factory

SZL series packaged water tube boiler has the advantages of compact structure, convenient installation, short install period, low cost, and environmental protect.

Learn more >> -

15ton SZL Series Water Tube Steam Boiler For UK Hotel Project

1. International famous brand electronic component (German Simens motor, Schneider electrical elements of electric control cabinet)

Learn more >>

2. Stainless steel impeller

3. Mute shock device on ID fan and impeller

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.