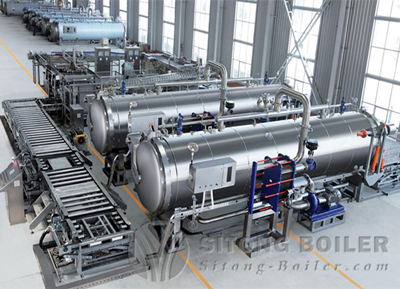

Autoclave Steam Sterilizer

- Capacity :600~4600L

- Pressure :<0.35MPa

- Temperature :<140℃

- Application : Canned food industry, pharmaceuticals industry, etc.

- Brief Intro :Autoclave steam sterilizer is a kind of hermetically sealed and pressurized heater, and used for sterilizing the food sealed in a container.

Email: [email protected]

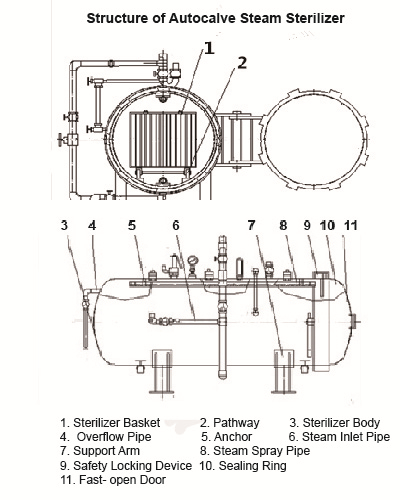

Autoclave steam sterilizer is a kind of hermetically sealed and pressurized heater, and used for sterilizing the food sealed in a container. Autoclave steam sterilizer is consisted of boiler body, cover, open-initiate system, locking wedge, safety interlock device, pathway, sterilization basket, and steam nozzle, etc.It is mainly used for food industry and pharmaceuticals industry, etc.

Autoclave steam sterilizer is a kind of hermetically sealed and pressurized heater, and used for sterilizing the food sealed in a container. Autoclave steam sterilizer is consisted of boiler body, cover, open-initiate system, locking wedge, safety interlock device, pathway, sterilization basket, and steam nozzle, etc.It is mainly used for food industry and pharmaceuticals industry, etc.

The autoclave steam sterilizercould be applied to a variety of high temperature packaging materials

1.plastic & rubber container: PP bottle, HDPE bottle, PP can, HDPE can

2.flexible package: aluminum foil bag, transparent bag, vacuum bag, retort pouch

3.Glass container: Glass bottle , glass jar

4.Metal can: tin can, aluminum foil can

Advantages

1. Multi-stage temperature, sterilize thoroughly

1. Multi-stage temperature, sterilize thoroughly

The sterilizer use high efficiency heat exchanger, the temperature rise up quickly, save energy. Set up different temperature based on different products, to make sure the taste, color, and nutrition are not be damaged.

2. Uniform temperature distribution

Set up pulse spraying device, hot water is sprayed in wave shape. There are several sprayer at each layer, to make sure the uniform temperature within the sterilizer.

3. Indirect heating, prevent secondary pollution

The circulation water is sent to heat exchanger by circulation pump for heating, the container will not contact with steam or water, prevent secondary pollution.

4. High quality sealing and material

The cover is sealed by inflatable silicon rubber sealing ring, reliable sealing, and long working life. The internal boiler body is made of stainless steel, acid-proof and heat-proof.

5. PLC automatic control

Adopts PLC automatic controller, could automatic adjust the temperature and pressure, operate automatically and conveniently.

6. Equipment customization

Sitong boiler could manufacture the specific products according to different customers’ requirements.

Parameter

| Capacity (L) | Design Pressure (MPa) | Working Pressure(MPa) | Design Temperature (℃) | Working Temperature(℃) | Diameter (mm) | Length (mm) |

| 600 | 0.35MPa | <0.3MPa | 140.7 | <135 | 700 | 1200 |

| 1400 | 0.35MPa | <0.3MPa | 140.7 | <135 | 900 | 1800 |

| 2200 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1000 | 2400 |

| 3000 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 2200 |

| 3600 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 2700 |

| 4000 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 3000 |

| 4200 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 3300 |

| 4600 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 3600 |

|

Notes: 1. Parameter is for reference only, if any changes should follow actual drawings. 2.We can design the specific autoclave steam sterilizer based on customers’ requirement. |

||||||

1. Multi-stage temperature, sterilize thoroughly

The sterilizer use high efficiency heat exchanger, the temperature rise up quickly, save energy. Set up different temperature based on different products, to make sure the taste, color, and nutrition are not be damaged.

2. Uniform temperature distribution

Set up pulse spraying device, hot water is sprayed in wave shape. There are several sprayer at each layer, to make sure the uniform temperature within the sterilizer.

3. Indirect heating, prevent secondary pollution

The circulation water is sent to heat exchanger by circulation pump for heating, the container will not contact with steam or water, prevent secondary pollution.

4. High quality sealing and material

The cover is sealed by inflatable silicon rubber sealing ring, reliable sealing, and long working life. The internal boiler body is made of stainless steel, acid-proof and heat-proof.

5. PLC automatic control

Adopts PLC automatic controller, could automatic adjust the temperature and pressure, operate automatically and conveniently.

6. Equipment customization

Sitong boiler could manufacture the specific products according to different customers’ requirements.

| Capacity (L) | Design Pressure (MPa) | Working Pressure(MPa) | Design Temperature (℃) | Working Temperature(℃) | Diameter (mm) | Length (mm) |

| 600 | 0.35MPa | <0.3MPa | 140.7 | <135 | 700 | 1200 |

| 1400 | 0.35MPa | <0.3MPa | 140.7 | <135 | 900 | 1800 |

| 2200 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1000 | 2400 |

| 3000 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 2200 |

| 3600 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 2700 |

| 4000 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 3000 |

| 4200 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 3300 |

| 4600 | 0.35MPa | <0.3MPa | 140.7 | <135 | 1200 | 3600 |

|

Notes: 1. Parameter is for reference only, if any changes should follow actual drawings. 2.We can design the specific autoclave steam sterilizer based on customers’ requirement. |

||||||

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.