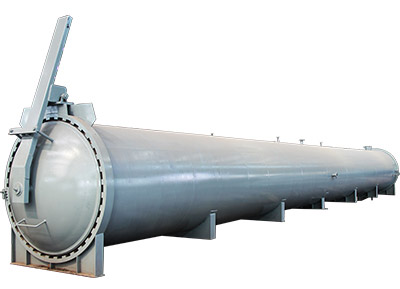

Wood (Timber) Preservative Tank

- Design Pressure :1.0-3.8 Mpa

- Design Temperature :187-225°C

- Length :According to the customers demands

- Application : wood preservation, mothproof, dyeing, coking, fire retardant, degrease, etc.

- Brief Intro :Sitong autoclave is large pressure vessel for steam curing, has excellent thermal insulating quality, it has the advantages of good treat efficiency, large capacity, reasonable layout, safety operation, etc.

Email: [email protected]

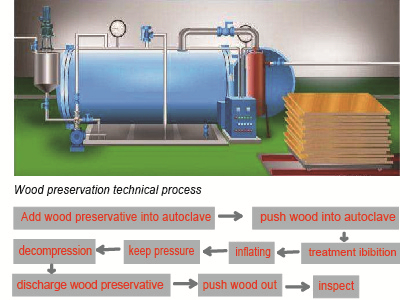

Wood Preservative Method

Pressure treatment - the wood were placed into an airtight steel cylinder and immersed in a preservative. Increasing pressure drives the chemical into the wood.

Wood Preservation Technical Process

Advantages of the pressure treatment over the non-pressure processes

- Deep, uniform penetration

- Better control over retention

- Wood can be pre-conditioned in the treatm ent chamber

- Faster and more reliable process

- More easily controlled and regulated

The effectiveness of a wood preservative largely depends on penetration and retention. The depth of penetration depends on the tree species, the proportion of sapwood to heartwood, and the treatment process used. A preservative penetrates the well-dried sapwood of most species more easily when pressure-treated but results with heartwood are more variable. Even with the proper preservative penetration, good protection cannot be achieved unless enough preservative stays in the wood. Preservative retention is measured in pounds per cubic foot (lbs/cu ft) of wood.

Technical Parameter

| ITEM | STANDARD | |

| Manufacturer Standard | GB | |

| Working Pressure | 7-30 bar | |

| Vacuum Degree | 0-0.98 bar | |

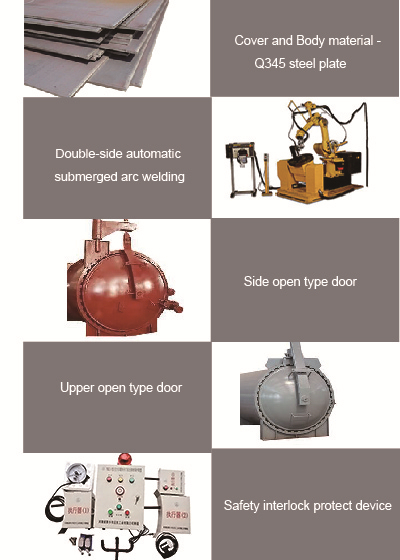

| Material | Q345, 16MnR | |

| Control System | Manual or Automatic Control | |

| Door Open | Manual Quick Open or Automatic | |

| Safety Measurement | Interlock Control and Protection | |

| Scope of Supply | Trolley, Track and Others Complete Set |

|

|

|||

Advantages of the pressure treatment over the non-pressure processes

- Deep, uniform penetration

- Better control over retention

- Wood can be pre-conditioned in the treatm ent chamber

- Faster and more reliable process

- More easily controlled and regulated

The effectiveness of a wood preservative largely depends on penetration and retention. The depth of penetration depends on the tree species, the proportion of sapwood to heartwood, and the treatment process used. A preservative penetrates the well-dried sapwood of most species more easily when pressure-treated but results with heartwood are more variable. Even with the proper preservative penetration, good protection cannot be achieved unless enough preservative stays in the wood. Preservative retention is measured in pounds per cubic foot (lbs/cu ft) of wood.

| ITEM | STANDARD | |

| Manufacturer Standard | GB | |

| Working Pressure | 7-30 bar | |

| Vacuum Degree | 0-0.98 bar | |

| Material | Q345, 16MnR | |

| Control System | Manual or Automatic Control | |

| Door Open | Manual Quick Open or Automatic | |

| Safety Measurement | Interlock Control and Protection | |

| Scope of Supply | Trolley, Track and Others Complete Set |

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.