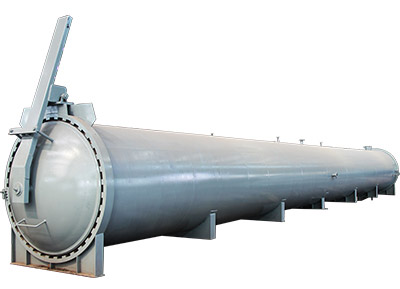

Industrial Electric Boiler

- Capacity :0.1t/h-6t/h

- Pressure :0.4~2.5 MPa

- Efficiency :99%

- Application : Food Processing, paper industry, food & beverage, diaries, schools, chemical industry, etc.

- Brief Intro :WDR horizontal electric boiler is a kind of high thermal efficiency (99%) and environment protect boiler.The boiler is full automatic boiler, the working life of ecartridge heater is about 2000 hours.

Email: [email protected]

WDR Series electric boiler is a kind of high thermal efficiency and environmental protect boiler. The thermal efficiency reaches as high as 99% without the problem of air pollution. It can be designed as vertical or horizontal type, to offer the sufficient output. The electrical control cabinet is separate from boiler body, which will not affect the boiler’s working life because of the aging of the electrical elements. The electric steam boiler adopts high quality stainless steel electric heating elements, has high compression strength, the life span is 5~10 times longer than the common heating elements.

Application

The industrial electric steam boiler is ideal for heating, textile plant, rice mill, garment factory, utility or power plant, hospital, hotel, food & beverage, diaries, schools, chemical industry and more applications.

Advantages

1. High thermal efficiency, long working life

1. High thermal efficiency, long working life

1) All the electrical components have the CE and CCC certification, to guarantee the safety operation and long working time.

2) Uses high quality seamless and stainless steel cartridge heaters, high compression strength, the thermal efficiency could reach 99%, and the working life is 5~10 times working life longer than others.

3) Each group electrical heating elements are connected by clustered flanges, simple structure, high mechanical strength, more safe and reliable.

2. Perfect automatic control

1) The boiler adopts PLC full automatic intelligent control cabinet, could set and control the water temperature.

2) Adopts interlock protect system, has the protect function on water shortage, over pressure, over temperature, flame out, electric leakage, and phrase-lacking or overloading of motor, etc., it could be adjusted conveniently.

3. Advanced circuit design

The boiler has advanced circuit design, the routing is net and reasonable, operate conveniently.

4. Sufficient output

The horizontal type boiler has relatively large steam space, to provide high quality steam output.

5. High quality welding

The boiler body use special steel plates, all the welding line is automatic welding, and detected by X-rays to ensure the quality.

6. High thermal shielding efficiency

The boiler shell use aluminium silicate board for heat preservation, high thermal shielding efficiency, low heat loss, save energy, and increase the boiler thermal efficiency.

7. Environmental protection

The boiler operates quietly and no harmful gas emission, meet the requirement of environmental protection.

Parameter

Steam Boiler

| Model | Rated Evaporation Capacity (t/h) | RatedWorking Pressure (Mpa) | RatedSteam Temperature (℃) | Thermal Efficiency (%) | Weight (kg) | |

| LDR0.1-0.4 | 0.1 | 0.4 | 151 |

99 |

1100 |

|

|

LDR0.2-0.4 |

0.2 |

0.4 |

151 |

99 |

1300 |

|

|

LDR0.3-0.4 |

0.3 |

0.4 |

151 |

99 |

1500 | |

|

LDR0.4-0.4 |

0.4 |

0.4 |

151 |

99 |

1700 | |

|

LDR0.5-0.4/0.7 |

0.5 | 0.4/0.7 | 151/170 |

99 |

1800 | |

|

LDR0.7-0.4/0.7 |

0.7 |

0.4/0.7 |

151/170 |

99 |

2500 | |

| WDR1-1.25 | 1 | 1.25 | 194 | 99 | 3230 | |

| WDR1.5-1.25 | 1.5 | 1.25 | 194 | 99 | 2600 | |

| WDR2-1.25 | 2 | 1.25 | 194 | 99 |

4900 |

|

| WDR3-1.25 | 3 | 1.25 |

194 |

99 |

6500 | |

| WDR4-1.25 | 4 |

1.25 |

194 |

99 |

7500 | |

|

WDR5-1.25 |

5 |

1.25 |

194 |

99 |

9000 | |

|

WDR6-1.25 |

6 |

1.25 |

194 |

99 |

10500 | |

| Note:Parameter is for reference only, if any changes should follow actual drawings. | ||||||

Hot Water Boiler

95/70

Model

Rated Power (KW)

RatedWorking Pressure (Mpa)

Rated Supply/Return Water Temperature (℃)

Thermal Efficiency (%)

Overall dimension (m)

Weight (kg)

CWDR0.7-0.7/85/60-D

700

0.7

85/60

98

3.05×1.85×1.75

2705

WDR1.05-1.0/95/70-D

1050

1.0

99

2.3×1.2×1.8

3000

WDR1.8-1.0/95/70-D

1800

1.0

99

4.6×2.2×2.3

6000

Note:Parameter is for reference only, if any changes should follow actual drawings.

1. High thermal efficiency, long working life

1) All the electrical components have the CE and CCC certification, to guarantee the safety operation and long working time.

2) Uses high quality seamless and stainless steel cartridge heaters, high compression strength, the thermal efficiency could reach 99%, and the working life is 5~10 times working life longer than others.

3) Each group electrical heating elements are connected by clustered flanges, simple structure, high mechanical strength, safe and reliable.

2. Perfect automatic control

1) The boiler adopts PLC full automatic intelligent control cabinet, could set and control the water temperature.

2) Adopts interlock protect system, has the protect function on water shortage, over pressure, over temperature, flame out, electric leakage, and phrase-lacking or overloading of motor, etc., it could be adjusted conveniently.

3. Advanced circuit design

The boiler has advanced circuit design, the routing is net and reasonable, operate conveniently.

4. Sufficient output

The horizontal type boiler has relatively large steam space, to provide high quality steam output.

5. High quality welding

The boiler body use special steel plates, all the welding line is automatic welding, and detected by X-rays to ensure the quality.

6. High thermal shielding efficiency

The boiler shell use aluminium silicate board for heat preservation, high thermal shielding efficiency, low heat loss, save energy, and increase the boiler thermal efficiency.

7. Environmental protection

The boiler operates quietly and no harmful gas emission, meet the requirement of environmental protection.

Steam Boiler

| Model | Rated Evaporation Capacity (t/h) | RatedWorking Pressure (Mpa) | RatedSteam Temperature (℃) | Thermal Efficiency (%) | Weight (kg) | |

| LDR0.1-0.4 | 0.1 | 0.4 | 151 |

99 |

1100 |

|

|

LDR0.2-0.4 |

0.2 |

0.4 |

151 |

99 |

1300 |

|

|

LDR0.3-0.4 |

0.3 |

0.4 |

151 |

99 |

1500 | |

|

LDR0.4-0.4 |

0.4 |

0.4 |

151 |

99 |

1700 | |

|

LDR0.5-0.4/0.7 |

0.5 | 0.4/0.7 | 151/170 |

99 |

1800 | |

|

LDR0.7-0.4/0.7 |

0.7 |

0.4/0.7 |

151/170 |

99 |

2500 | |

| WDR1-1.25 | 1 | 1.25 | 194 | 99 | 3230 | |

| WDR1.5-1.25 | 1.5 | 1.25 | 194 | 99 | 2600 | |

| WDR2-1.25 | 2 | 1.25 | 194 | 99 |

4900 |

|

| WDR3-1.25 | 3 | 1.25 |

194 |

99 |

6500 | |

| WDR4-1.25 | 4 |

1.25 |

194 |

99 |

7500 | |

|

WDR5-1.25 |

5 |

1.25 |

194 |

99 |

9000 | |

|

WDR6-1.25 |

6 |

1.25 |

194 |

99 |

10500 | |

| Note:Parameter is for reference only, if any changes should follow actual drawings. | ||||||

Hot water boiler

| Model | Rated Power (KW) | RatedWorking Pressure (Mpa) | Rated Supply/Return Water Temperature (℃) | Thermal Efficiency (%) | Overall dimension (m) | Weight (kg) |

|

CWDR0.7-0.7/85/60-D |

700 | 0.7 | 85/60 | 98 | 3.05×1.85×1.75 | 2705 |

| WDR1.05-1.0/95/70-D | 1050 | 1.0 |

95/70 |

99 | 2.3×1.2×1.8 | 3000 |

| WDR1.8-1.0/95/70-D | 1800 | 1.0 | 99 | 4.6×2.2×2.3 | 6000 | |

|

Note:Parameter is for reference only, if any changes should follow actual drawings. |

||||||

Case

- 1

- 2

-

1t/h Electric Heating Boiler For Ethiopia University Kitchen

1. All the electrical elements have the CE and CCC certification to make sure the boiler safety and long live.

Learn more >>

2. Each group electrical heating elements focus on type of flange connection to make the structure simple, safe and easy to repair. -

1500000 kcal/h WDR Series Electric Heating Boiler for Vietnam Farming

The electrical control cabinet separate from boiler body, which will not affect the boiler’s working life because of the aging of the electrical elements.

Learn more >>

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.